Views: 0 Author: Site Editor Publish Time: 2025-09-22 Origin: Site

In modern construction, drywall systems have become a staple for interior walls and ceilings. Their speed, versatility, and cost-effectiveness make them a preferred choice over traditional masonry walls. Central to a durable drywall installation is the proper use of light steel keels, also known as drywall studs and tracks. These components provide the structural framework that supports the drywall panels, ensuring stability, longevity, and safety. This article will guide you through the correct use of drywall stud and track profiles, common mistakes to avoid, and best practices for achieving a professional installation.

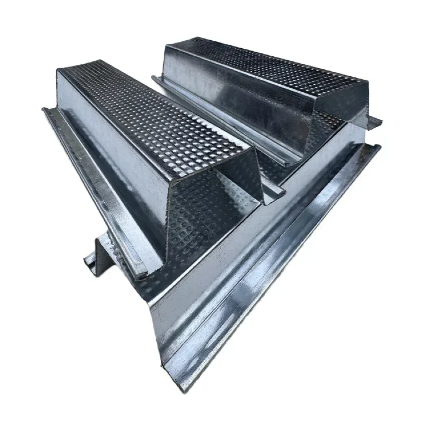

Drywall frameworks are composed of two primary components:

Studs: Vertical members that form the wall’s skeleton. These are typically made from light-gauge steel, providing strength without adding excessive weight. Studs come in various sizes and thicknesses depending on wall height, load requirements, and fire resistance specifications.

Tracks: Horizontal members fixed to the floor and ceiling to hold the studs in place. Tracks create a secure boundary for the studs, allowing them to stand upright and maintain consistent spacing.

Together, studs and tracks form a rigid framework that supports drywall panels while accommodating wiring, plumbing, and insulation. Proper selection and installation of these components are critical for wall performance.

Material Quality

Choosing high-quality light steel keels ensures the wall’s durability and safety. Look for corrosion-resistant steel with uniform thickness, smooth edges, and consistent dimensions. Inferior materials may warp, bend, or fail over time.

Wall Design and Load Requirements

Understand the purpose of the wall. For non-load-bearing partitions, standard 50mm or 75mm studs may suffice. For load-bearing walls or ceilings, thicker studs with heavier gauge steel may be required. Consult engineering specifications if necessary.

Environmental Conditions

Steel studs can be affected by moisture. In high-humidity areas, choose galvanized or treated steel to prevent rust. For fire-rated walls, ensure the studs meet local fire code requirements.

Proper installation of drywall stud and track profiles is crucial for achieving straight, stable, and durable walls. The following step-by-step guide provides detailed instructions and tips to ensure a professional finish.

Begin by measuring and marking the exact location of the wall on both the floor and ceiling using a chalk line. Precise markings are essential to avoid misalignment that could lead to uneven walls.

Secure the tracks to the floor and ceiling using anchors or screws suitable for the substrate. For concrete floors, use expansion anchors or concrete screws; for wooden floors or joists, wood screws or lag bolts are appropriate.

Check alignment carefully: tracks must be perfectly parallel and straight. Use a laser level or long spirit level to ensure accuracy. Misaligned tracks will cause studs to be skewed, leading to gaps or warped drywall surfaces.

Consider applying a rubber or foam strip under the tracks to reduce vibration, sound transmission, and potential moisture transfer.

Measure the vertical distance between the floor and ceiling tracks at multiple points to account for any uneven surfaces.

Cut the studs using metal shears, a fine-tooth saw, or a power metal-cutting tool to ensure clean, straight edges. Burrs or rough edges can make installation more difficult and may damage drywall panels.

Allow for slight adjustments in length to accommodate flooring variations, ceiling height differences, or leveling corrections. Test-fit a few studs before cutting the full batch.

Place each stud vertically within the floor and ceiling tracks, maintaining consistent spacing—typically 16 inches (400 mm) or 24 inches (600 mm) on center depending on the drywall thickness and load requirements.

Use a spirit level or laser level to ensure each stud is plumb. Accurate vertical alignment is critical to prevent wall bulging or misaligned panels.

Secure each stud to the track using self-tapping screws designed for steel studs. Position screws near both top and bottom flanges. Avoid over-tightening, which can deform the steel or compromise structural integrity.

For taller walls, consider temporarily bracing studs with a straightedge or lightweight string line to maintain alignment until all studs are fixed.

Walls that will support cabinets, shelves, televisions, or heavy fixtures require additional blocking or horizontal bracing between studs. Use steel channels or wood blocks cut to fit snugly within the studs.

Reinforce corners and intersections with additional studs or metal angles to prevent cracking at joints. These areas experience higher stress, especially during drywall installation and finishing.

If installing double-layer drywall for enhanced soundproofing or fire resistance, ensure reinforcements accommodate the extra thickness.

Drill holes in the center web of studs for electrical wiring, plumbing pipes, or low-voltage conduits. Ensure holes do not exceed one-third of the stud width to maintain structural integrity.

Keep wires and pipes neatly organized to avoid interference with drywall screws and to simplify future maintenance.

Avoid creating multiple large openings close to one another, as this can weaken the stud and reduce wall stability. Use metal grommets or bushings to protect wires and pipes passing through steel studs.

Position drywall sheets against the stud framework, starting from one corner and working across the wall. Ensure panels are flush with adjacent panels to minimize joint gaps.

Use screws designed for steel studs, typically spaced every 16 inches along panel edges and 24 inches in the field. Countersink screws slightly without tearing the drywall paper.

Check for panel alignment and levelness as you go. Small adjustments are easier to make before finishing.

Stagger the joints of successive drywall sheets to improve wall stability and reduce the appearance of seams during finishing.

Once all panels are installed, inspect the wall for gaps, protruding screws, or uneven edges before applying joint tape and compound.

Incorrect Stud Spacing

Spacing studs too far apart can cause wall sagging or panel cracking. Always follow recommended spacing guidelines for the drywall thickness.

Misaligned Tracks

If floor and ceiling tracks are not perfectly parallel, walls may bow, creating uneven surfaces that complicate finishing.

Overdriving Screws

Over-tightening screws can bend or deform studs, reducing structural integrity. Screw heads should sit flush with the drywall surface.

Ignoring Moisture Protection

Failure to use galvanized or treated steel in humid areas can lead to rust, compromising both strength and aesthetics.

Double-check all measurements before cutting or installing studs.

Use a plumb line or laser level for accurate vertical alignment.

Keep screws and fasteners consistent to avoid uneven panel surfaces.

Consider adding insulation between studs for soundproofing or thermal efficiency.

Finish joints with tape and joint compound for smooth, professional walls ready for painting or wallpaper.

Using light steel keels offers multiple benefits over traditional wood framing:

Durability: Steel is resistant to warping, cracking, and termite damage.

Precision: Manufactured steel studs have uniform dimensions, making installation faster and more accurate.

Lightweight: Easier to handle compared to timber, reducing labor strain.

Fire Resistance: Steel does not burn, improving building safety.

Recyclability: Steel is environmentally friendly and can be recycled at the end of the building’s lifecycle.

Proper use of drywall stud and track profiles is essential for constructing walls that are strong, straight, and long-lasting. By selecting high-quality light steel keels, adhering to correct spacing and alignment, and avoiding common mistakes, builders and DIY enthusiasts can achieve professional-grade results.

For companies and contractors looking for reliable light steel keel systems and drywall framing solutions, Yingbang International Trade (dongguan) Co., Ltd. offers high-quality materials designed for durability, precision, and ease of installation. For more information or to explore suitable products for your construction projects, consider contacting their team for expert guidance and support.